Geprüfte Sicherheit. Planbar bis ins Detail.

Für Architekten & Planer im Sicherheits- und Sonderbau sowie im Denkmalschutz: RC-/FB-klassifizierte Elemente, dokumentierte Nachweise, BIM/CAD und klare Schnittstellen.

Was Sie von uns erwarten dürfen

Keine Floskeln: Fokus auf Nachweise, Schnittstellen und belastbare Planungsdaten.

Prüfzeugnisse & Konformität

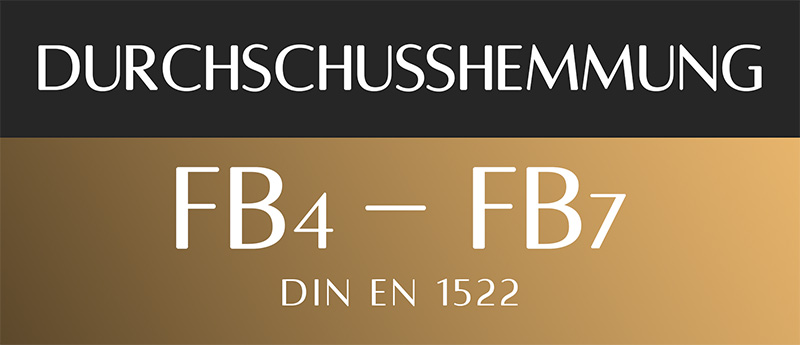

RC 2–RC 4, Ballistik bis FB 7 sowie Kombinationsanforderungen (z. B. Schall/Brand) mit dokumentierbaren Grundlagen.

BIM/CAD & Details

Schnittstellen, Anschlussdetails und Systemlogik – damit Ausschreibung und Ausführung konsistent bleiben.

Manufaktur & Einzelfertigung

Komplexe Geometrien, Sonderprofile, denkmalgerechte Ansichten – ohne Standardzwang.

Unsere Systeme im Überblick

Holz, Holz-Alu oder Aluminium – mit definierter Schutzklasse, klaren Schnittstellen und sauberer Dokumentation.

RC / FB / Kombinationen

- Einbruchhemmung RC 2–RC 4

- Optional: Ballistik bis FB 7

- Kombinationen mit Schall/Brand nach Bedarf

Objektbau & Sonderanforderungen

- RC-klassifizierte Türsysteme

- Optionen: Brand/Schall/Zutritt je nach Konzept

- Abnahmeorientierte Dokumentation

Historische Optik – moderne Funktion

- Profilierung, Ansichtsbreiten, Oberflächen

- Nachrüstbar mit Sicherheits- und Energielogik

- Koordination mit Behörden & Fachplanern

Weitermachen, wo andere aufhören.

Außergewöhnliche Architektur stellt besondere Anforderungen: Übergrößen, Sonderformen, anspruchsvolle Anschlüsse oder Mehrfachanforderungen (z. B. RC/FB mit Schall/Brand). Entscheidend ist, dass Parameter, Schnittstellen und Nachweislogik früh zusammengeführt werden.

Typische Projektknoten

- Laibung/Abdichtung/Befestigung (Einbau-Logik)

- Beschlag-/Glas-/Rahmensystem als Gesamtnachweis

- Übergaben und Abnahmekriterien als Deliverables

Wenn Sie möchten, starten Sie direkt mit unserem Wizard – er stellt die richtigen Fragen.

Referenzen – diskret, aber nachvollziehbar

Viele Projekte unterliegen Vertraulichkeit. Wir zeigen Beispiele, die Struktur, Detailtiefe und Abwicklung abbilden.

Historische Profilierung + unsichtbare Technik

Wenn Gestaltung und Schutzanforderung nicht verhandelbar sind, muss die Lösung im Detail funktionieren.

Vergabe & Abnahme

Klare Nachweise, konsistente Dokumente und definierte Schnittstellen sind entscheidend.

Kombinationen

Brand/Schall/Einbruch/Ballistik greifen ineinander – Spezifikation und Systemlogik müssen zusammenpassen.

Projektbeispiele ansehen

Mit Filtern (Kategorie) und Suchbegriffen (z. B. RC 4, Ballistik, BIM).

Seit 1681 – Tradition als Qualitätsstandard

Aus einer Schreinerei in Münster wurde eine Manufaktur für Premium-Sicherheitslösungen. Der Anspruch bleibt: handwerklich präzise, technisch belastbar, dokumentiert abnahmefähig.

„Perfektion ist kein Zufall – sondern Prozess.“ Wir denken Planung, Details und Umsetzung zusammen.

Für die Planung relevant

- Feste Ansprechpartner & klare Rückfragenlogik

- Planungsdaten (BIM/CAD) nach Projektstand

- Detailknoten und Schnittstellen als definierte Deliverables

Was Kunden und Partner schätzen

Kurze Auszüge aus Rückmeldungen – ohne Namen, dafür mit Kontext.

„Sicherheit – ohne sichtbare Kompromisse.“

Die Abstimmung war strukturiert, die Details passten – und das Ergebnis wirkt wie ein normales Premium-Element, nicht wie eine „Sicherheitslösung“.

Privatvilla (Bestand), Norddeutschland

„Klare Unterlagen – weniger Rückfragen auf der Baustelle.“

Wenn Schutzklasse und Schnittstellen sauber definiert sind, können wir Montage und Gewerkeübergaben deutlich effizienter koordinieren.

Montage-/Ausbaupartner, NRW

„Planbarkeit war entscheidend.“

Wir brauchten eine belastbare Spezifikation für Ausschreibung und Abnahme. RvE hat die Anforderungen früh sortiert und konsequent dokumentiert.

Öffentlicher Auftraggeber (Objektbau)

„Eine Manufaktur, die Denkmallogik versteht.“

Bei Bestand und Denkmal zählen Profilierung, Ansichten und Details. Gut, wenn das Team sowohl gestalterisch als auch technisch argumentieren kann.

Planungs-/Architekturpartner, Süddeutschland

Häufige Fragen – kurz beantwortet

Für die erste technische Einschätzung reichen wenige Angaben. Details klären wir strukturiert im Erstgespräch.

Welche Angaben braucht RvE?

Objektart, Projektkontext (Neubau/Bestand/Denkmal), gewünschte Schutzklassen und die Einbausituation/Details.

Gibt es BIM/CAD?

Ja – abhängig vom Systemstand. Wir stellen Planungsdaten passend zur Schnittstelle bereit.

Sonderlösungen = Risiko?

Nicht automatisch. Risiko entsteht durch unklare Anforderungen – nicht durch Geometrie.

Anfrage starten – strukturiert, technisch, effizient.

Kurze Anfrage oder Wizard: Schutzbedarf + Kontext + Besonderheiten.